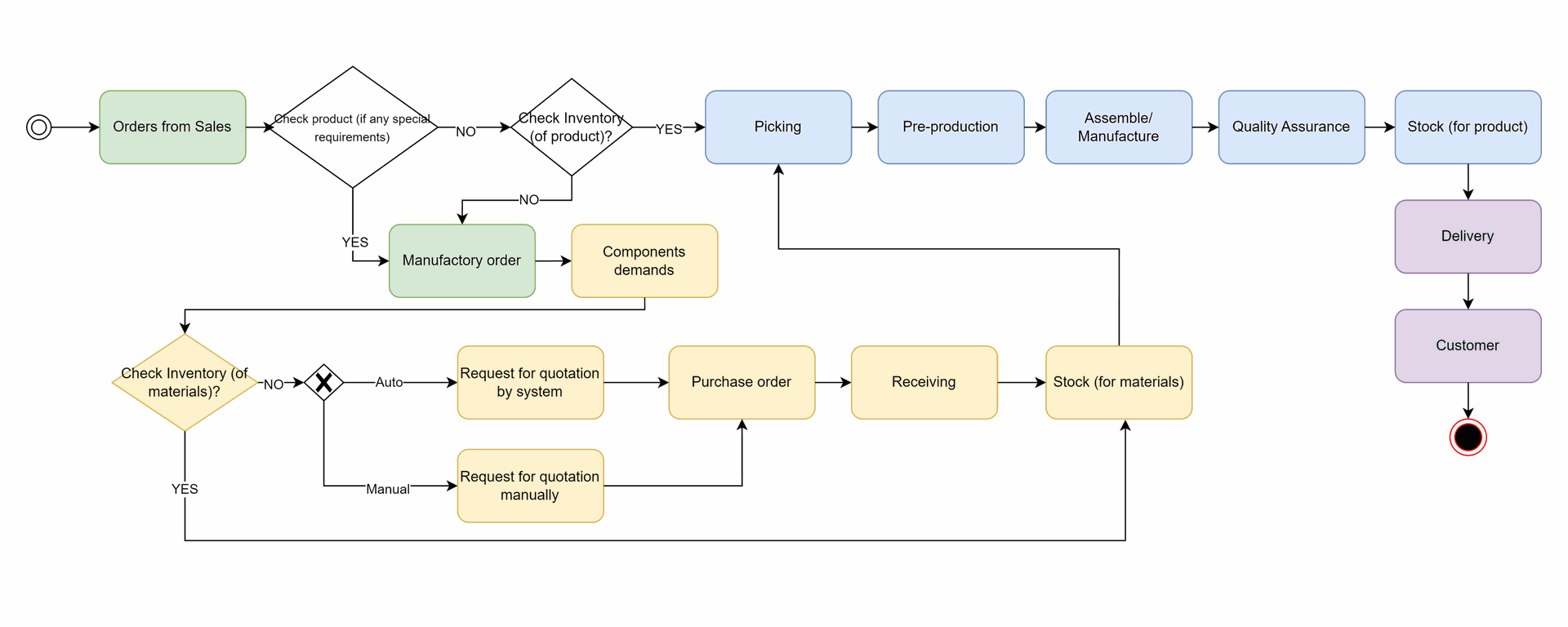

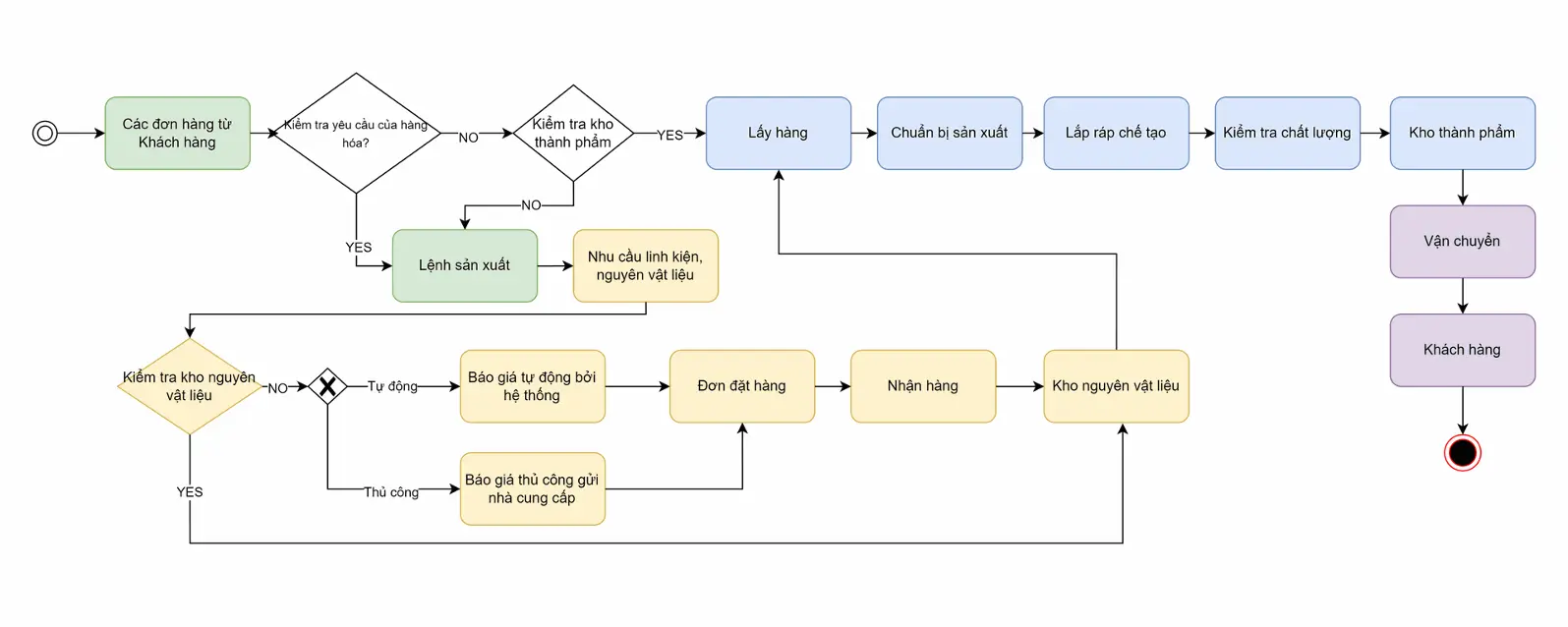

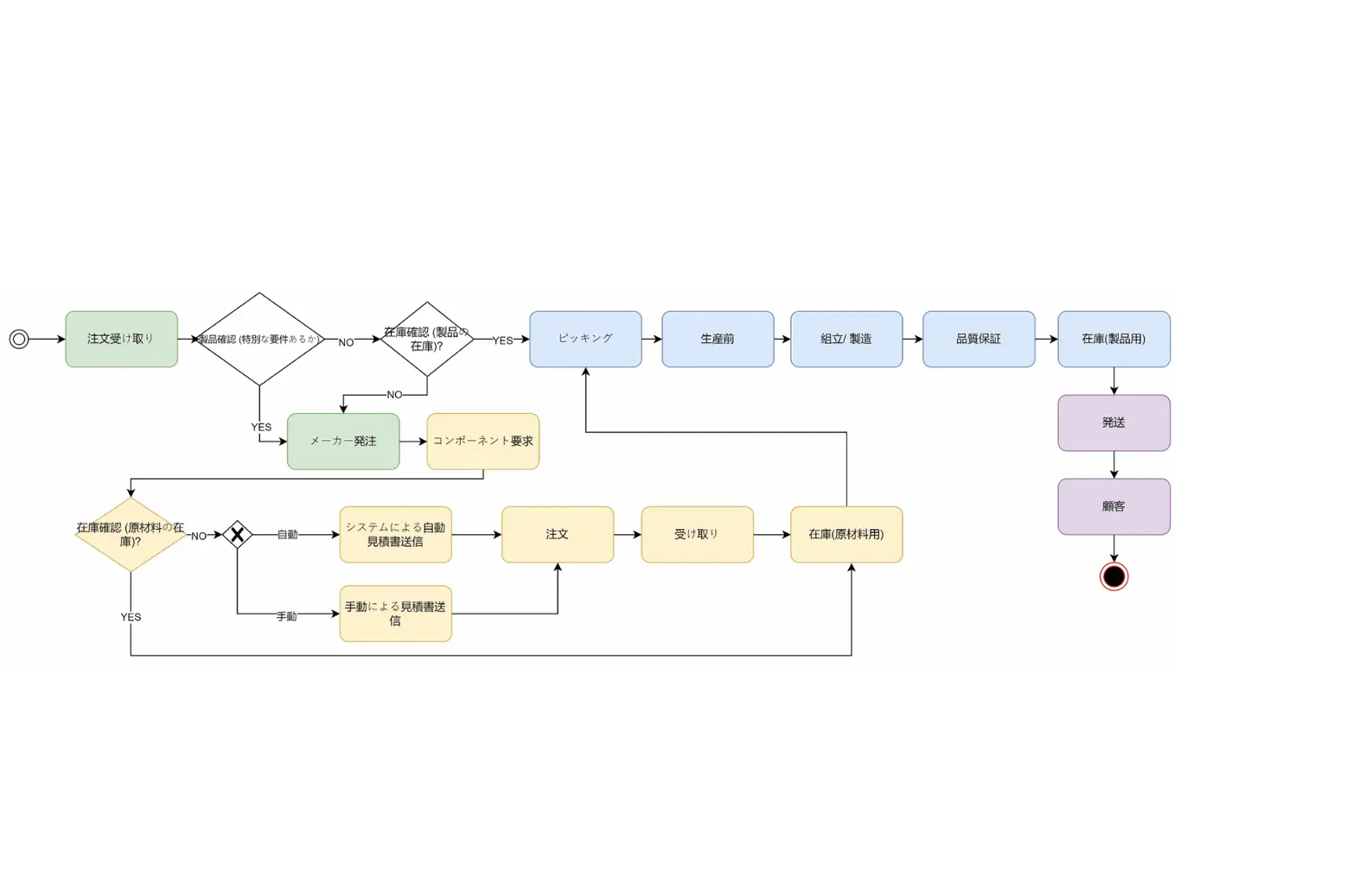

Material requirements planning in manufacturing industry

A key aspect of manufacturing operations, Material Requirements Planning systems are designed to ensure that materials and products are available for production and delivery to customers, maintaining the lowest possible level of inventory while maximizing efficiency and productivity.

Challenges That Manufacturing Companies Are Facing

Manual record-keeping of goods and raw materials results in outdated information, leading to overstock or stockouts, damaging sales and reputation. As e-commerce sales surge, managers struggle to identify trending items, hindering timely restocking. Poor inventory management also increases the risk of employee fraud and financial losses due to price slippage.

Why choose Inventory

Management System (IMS)?

Balance the amount of goods needed in the warehouse

Optimize inventory turnover

Helps accurately orient business

Customer retention

Take charge of your warehouse with our tailored inventory control solutions

Productivity

Scheduler triggers operations automatically based on product availability and forecasts of orders.

Live web page where customers can track the status of their order, payment, and delivery status.

Reporting

Full stock moves report to map and trace product moves from supplier to customer.

Monitor how long items have been in the warehouse. Quantities are sorted by receipt date, allowing you to stay informed about products nearing expiration.

Why choose us?

Cost and Time Savings with PeaSoft Development

By developing the PeaSoft package, the company can reduce costs and save time in managing warehouse operations

Real-Time Product Feedback for Customers

The customer can view the status of products at each stage of the warehouse process, allowing them to quickly provide feedback or suggestions that align with their actual requirements

Comprehensive Customer Support and Training

The customer receives comprehensive support, including product training and assistance with all questions related to the product during its operation

Transform Your Future with

Cutting-Edge Software Innovation!

Elevate your software with our innovation experts, ensuring seamless user experiences every step of the way.